Industrial Uses of Galvo for Laser Marking, Inscription, and Reducing Applications

Industrial Uses of Galvo for Laser Marking, Inscription, and Reducing Applications

Blog Article

Trick Features to Think About When Picking a Galvo for Your Jobs

When selecting a galvo for your projects, it is critical to examine numerous functions that directly affect performance and outcomes. Elements such as precision, rate, and resolution can significantly affect the high quality of your job, while compatibility with control software and surveillance capabilities enhance functional effectiveness.

Rate and Performance

High-speed galvos allow faster handling times, which is important for making the most of throughput in manufacturing atmospheres. When assessing galvos, think about the optimum angular speed, usually measured in degrees per 2nd, as well as the settling time, which impacts just how rapidly the system can stabilize after a command. Furthermore, the velocity capabilities of the galvo play a considerable duty in attaining optimum efficiency, particularly in applications including high-density patterns or complex trajectories.

Moreover, the functional bandwidth needs to be assessed, as it determines the series of regularities at which the galvo can properly run. Ultimately, picking a galvo that straightens with your certain speed and performance needs will make certain that your jobs achieve the wanted effectiveness and effectiveness.

Accuracy and Resolution

When selecting a galvo for precision applications,Attaining high precision and resolution is essential. The accuracy of a galvo system is frequently defined by its capacity to position the laser beam of light precisely at the wanted coordinates. Galvo Motor. This accuracy is critical in applications such as laser engraving, marking, and reducing, where even small deviations can cause significant high quality problems

Resolution, on the other hand, refers to the tiniest distinguishable function that the galvo can generate. It is important in identifying the degree of information possible in the last outcome. Greater resolution enables the recreation of elaborate designs with fine information, making it essential for industries that call for high-grade results, such as medical tool manufacturing and microelectronics.

When evaluating a galvo's accuracy and resolution, take into consideration specifications such as angular resolution and linearity. A lower angular resolution shows much better accuracy, while linearity ensures that the system behaves predictably across its whole functional array. Understanding these parameters makes it possible for notified decision-making in picking a galvo that satisfies the specific needs of your job, making sure ideal efficiency and quality in final end results.

Control and Software Compatibility

The integration of control systems and software application compatibility plays a substantial duty in the general performance of a galvo system, especially in precision applications where precision and resolution have actually already been established as vital elements. Galvo Scanner. A well-integrated control system enables smooth interaction between the galvo and the host computer, making certain that commands are executed promptly and precisely

When choosing a galvo, it is crucial to consider the compatibility with existing software application platforms. In addition, the ability to interface with various programs languages and APIs can considerably improve the usability of the galvo system.

In addition, the existence of real-time surveillance and responses mechanisms within the control software application is crucial. These features not just help with error detection however likewise permit modifications during procedure, boosting overall system performance. Eventually, ensuring that the galvo's control and software application line up with your job demands will add to attaining optimum cause your applications.

Build High Quality and Durability

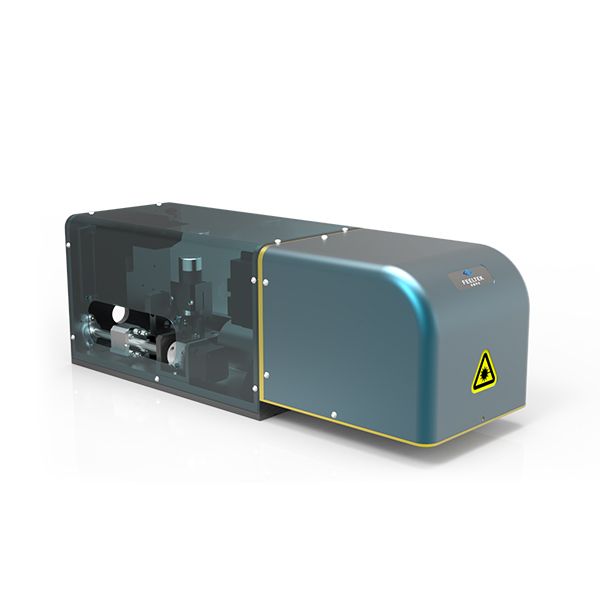

While factors such as control compatibility are important, the construct top quality and durability of a galvo system are just as vital for making certain long-term performance and integrity. A well-constructed galvo will certainly endure the roughness of continuous operation, particularly popular settings. Products made use of in the housing and parts directly influence the system's resistance to use, rust, and thermal variations.

When examining develop top quality, take into consideration not only the exterior materials but additionally the interior systems. High-grade optics, durable motors, and precision design add to accurate efficiency and reduced upkeep requirements. Galvo Scanner. Suppliers that focus on strenuous testing and quality assurance in their production processes typically offer systems that display remarkable integrity over time

Longevity additionally includes the system's capability to operate under differing environmental problems, such as temperature level extremes and moisture. A galvo made for resilience will decrease downtime and operational disruptions, which can be important in commercial settings.

Investing in a galvo with proven construct high quality and resilience will Home Page eventually improve efficiency and decrease the frequency of repair work or replacements, making it a sound choice for any project calling for precision and uniformity.

Cost and Budget Plan Factors To Consider

When evaluating alternatives for a galvo budget, cost and system factors to consider play a crucial function in the decision-making procedure,. It is click to read more vital to understand that the first purchase rate is just one part of the overall expense. Extra factors such as maintenance, functional expenditures, and prospective upgrades need to likewise be factored into the budget.

A reduced in advance price might be tempting; however, it is crucial to analyze the long-lasting reliability and performance of the system. Affordable versions may sustain greater prices gradually because of constant repairs or poor efficiency. Conversely, purchasing a higher-quality galvo might bring about greater effectiveness and lowered downtime, eventually conserving money in the future.

Moreover, take into consideration the specific demands of your jobs. A tailored option can usually be more affordable than a one-size-fits-all strategy. It is advisable to collect multiple quotes, evaluating each alternative's features and assistance solutions, thereby ensuring that your investment lines up with your task's requirements and spending plan restrictions.

Conclusion

In conclusion, choosing an appropriate galvo for particular projects demands mindful consideration of multiple factors. A comprehensive evaluation of these vital attributes will inevitably lead to informed decision-making and effective task end results.

The speed of a galvo is typically defined by its response time and scanning speed, both of which establish the effectiveness of the system. When evaluating galvos, think about the maximum angular velocity, commonly gauged in levels per 2nd, as well as the working out time, which affects exactly how swiftly the system can support reference after a command. The accuracy of a galvo system is usually defined by its ability to position the laser beam of light exactly at the preferred collaborates.While aspects such as control compatibility are important, the develop top quality and toughness of a galvo system are similarly crucial for making sure lasting performance and dependability.When evaluating options for a galvo expense, spending plan and system factors to consider play a crucial duty in the decision-making process.

Report this page